Dealing with stubborn clogs in your plumbing system can be frustrating, but the right tools and techniques make all the difference. A drain snake represents one of the most effective solutions for homeowners and professionals alike when facing persistent blockages that resist conventional methods. This versatile plumbing tool can navigate through pipes, break up debris, and restore proper water flow without the need for harsh chemicals or expensive service calls.

Professional plumbers have relied on drain snakes for decades, and modern homeowners are discovering the benefits of having this essential tool readily available. Whether you're dealing with hair clogs in bathroom drains, grease buildup in kitchen sinks, or tree root intrusions in main sewer lines, understanding proper drain snake techniques can save both time and money while preventing recurring drainage issues.

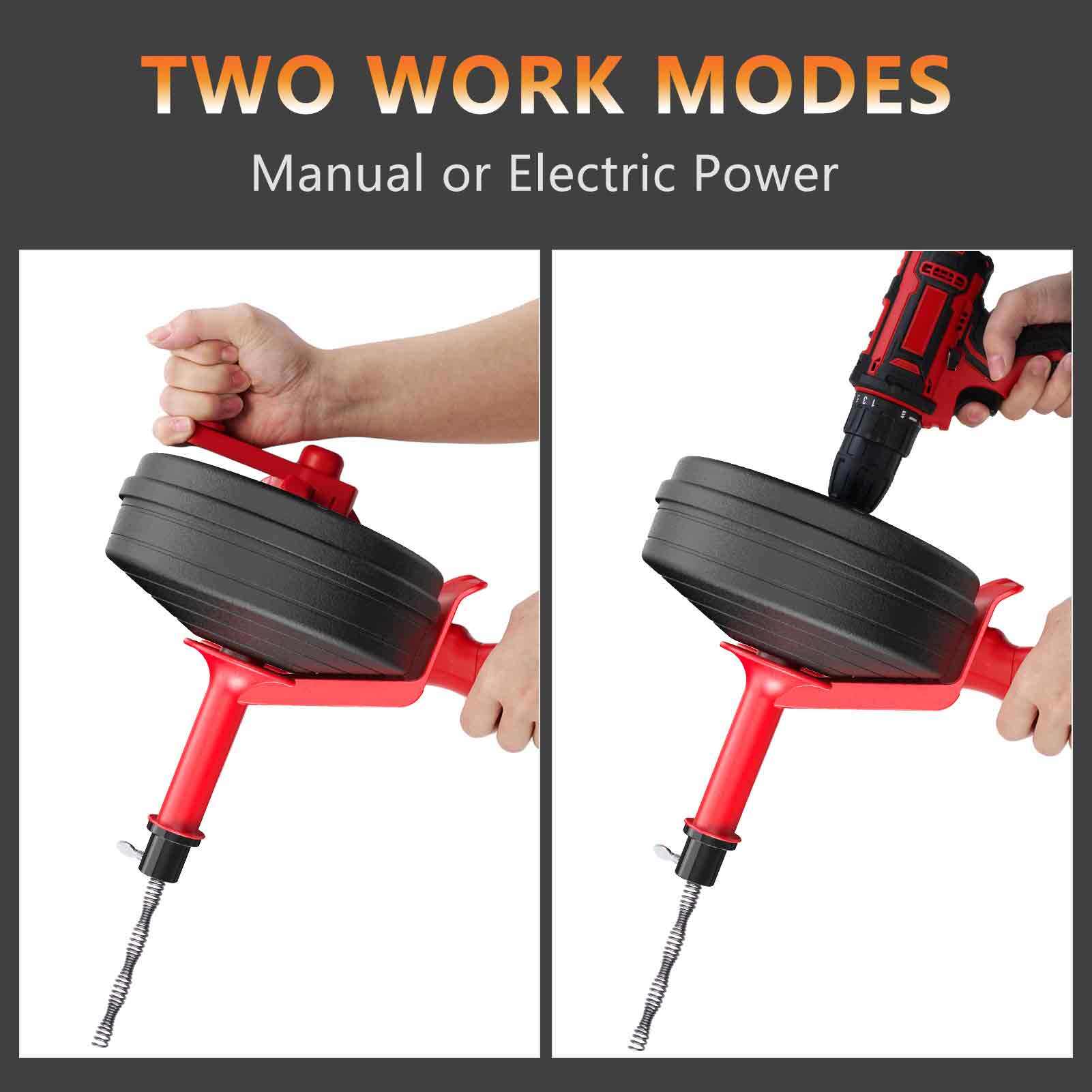

Understanding Different Types of Drain Snakes

Manual Drain Snakes

Manual drain snakes offer precise control and work exceptionally well for smaller residential clogs. These hand-operated tools typically feature a flexible cable ranging from 25 to 100 feet in length, with various head attachments designed for specific types of blockages. The operator controls the rotation and advancement manually, allowing for careful navigation through pipe bends and joints without causing damage to the plumbing system.

The advantage of manual operation lies in the tactile feedback provided to the user. When the drain snake encounters resistance, experienced operators can feel the difference between a solid blockage and a pipe bend, adjusting their technique accordingly. This sensitivity helps prevent pipe damage while ensuring thorough clog removal throughout the affected drain line.

Electric Drain Snakes

Electric models provide additional power for tackling more stubborn blockages, making them ideal for commercial applications and severe residential clogs. These machines feature motorized rotation mechanisms that maintain consistent pressure and speed, reducing operator fatigue during extended use. Most electric drain snakes include variable speed controls and reversible motors for enhanced versatility.

Professional-grade electric units can handle cables up to 300 feet long, making them suitable for main sewer line cleaning and industrial applications. The increased power allows these machines to break through dense root masses, accumulated grease, and mineral deposits that would challenge manual alternatives, ensuring comprehensive drain clearing results.

Specialized Snake Attachments

Different clog types require specific attachment heads to achieve optimal results. Cutting blades work best for root intrusions and solid obstructions, while spiral augers excel at grabbing hair, fabric, and similar debris. Spear-point heads can pierce through soft blockages, and cleaning heads help remove pipe scale and buildup along drain walls.

Selecting the appropriate attachment for each situation significantly improves cleaning effectiveness while reducing the risk of pipe damage. Many professional drain snakes include interchangeable head systems, allowing operators to switch between different attachment types based on the specific blockage encountered during the cleaning process.

Proper Drain Snake Techniques

Initial Assessment and Preparation

Before deploying a drain snake, conduct a thorough assessment of the drainage problem to determine the most appropriate approach. Check water levels, identify the approximate location of the blockage, and gather information about recent drain usage patterns. This preliminary evaluation helps select the right drain snake size and attachment configuration for the specific situation.

Preparation also involves protecting the surrounding area from potential water damage and debris. Place towels around the work area, ensure adequate lighting, and have cleaning supplies readily available. Proper preparation prevents secondary issues while creating an efficient working environment for successful drain cleaning operations.

Entry Point Selection

Choosing the optimal entry point dramatically affects the success of drain snake operations. For kitchen sinks, the trap cleanout provides direct access to the drain line, while bathroom applications might require removal of the overflow plate or drain stopper. Main sewer line access typically involves outdoor cleanout ports or roof vent entries.

Consider the shortest path to the blockage when selecting entry points, as this reduces the likelihood of the drain snake becoming tangled or damaged during insertion. Multiple access points might be necessary for complex blockages or extensive drain systems, requiring strategic planning and systematic approach to achieve complete clog removal.

Cable Insertion and Navigation

Insert the drain snake cable slowly and steadily, maintaining consistent forward pressure while rotating the cable clockwise. This rotation helps the cable navigate through pipe bends while the cutting head breaks up debris encountered along the way. Avoid forcing the cable, as excessive pressure can cause pipe damage or cable binding within the drain system.

When resistance increases, distinguish between blockage contact and pipe bends through careful manipulation. Blockages typically create inconsistent resistance that varies with rotation, while pipe bends produce steady resistance that changes with cable angle adjustment. Understanding these differences prevents unnecessary force application and potential plumbing damage.

Safety Considerations and Best Practices

Personal Protection Equipment

Working with drain snakes requires appropriate safety equipment to protect against exposure to contaminated water, sharp cable edges, and potential chemical residues. Wear rubber gloves, safety glasses, and protective clothing that can be easily cleaned or disposed of after completing the drain cleaning task. Face masks help prevent inhalation of sewer gases and airborne contaminants.

Electric drain snake operations require additional precautions, including ground fault circuit interrupter protection and dry working conditions. Ensure all electrical connections remain protected from water exposure, and never operate electric equipment with wet hands or in standing water situations that could create electrocution hazards.

Avoiding Common Mistakes

One frequent error involves using excessive force when encountering resistance, which can damage pipes or cause cable breakage within the drain system. Instead, work patiently and systematically, allowing the drain snake to do the work through proper technique rather than brute force application. This approach prevents costly repairs while ensuring effective blockage removal.

Another common mistake involves inadequate cable cleaning between uses, which can transfer contaminants between different drain systems and reduce tool lifespan. Clean and disinfect the entire cable length after each use, inspect for damage or wear, and store the equipment properly to maintain optimal performance for future applications.

When to Call Professionals

Certain situations exceed the capabilities of standard residential drain snakes and require professional intervention. These include main sewer line blockages, recurring clogs that resist multiple cleaning attempts, and situations involving potential pipe damage or structural issues. Professional plumbers have access to advanced equipment and expertise necessary for complex drain problems.

Signs that warrant professional assistance include gurgling sounds from multiple drains, sewer odors throughout the building, or water backing up in unexpected locations. These symptoms often indicate systemic problems that require comprehensive evaluation and specialized equipment beyond typical homeowner drain snake capabilities.

Maintenance and Storage

Regular Equipment Maintenance

Proper maintenance extends drain snake lifespan while ensuring reliable performance when needed most. Clean the entire cable thoroughly after each use, removing all debris and contaminants that could cause corrosion or bacterial growth. Apply appropriate lubricants to mechanical components, and inspect the cable for kinks, fraying, or other damage that could compromise effectiveness.

Electric models require additional maintenance attention, including motor inspection, electrical connection checks, and periodic professional servicing. Keep replacement parts readily available, such as cutting heads and cable sections, to minimize downtime when repairs become necessary during critical drain cleaning operations.

Proper Storage Techniques

Store drain snake equipment in a clean, dry environment that prevents rust formation and cable deterioration. Coil cables loosely to prevent permanent kinking, and protect cutting heads from damage during storage. Many professional units include dedicated storage containers that organize components while protecting them from environmental damage.

Inventory all components regularly, ensuring that attachment heads, cables, and accessories remain complete and ready for use. This proactive approach prevents delays during emergency drain cleaning situations while maintaining professional standards for equipment care and organization throughout the tool's service life.

Advanced Techniques for Challenging Blockages

Root Intrusion Management

Tree root intrusions present unique challenges that require specialized drain snake techniques and attachments. Root-cutting heads feature sharp blades designed to slice through fibrous root masses, while high-torque motors provide the power necessary for effective cutting action. Work systematically from the access point toward the main blockage, clearing smaller roots before tackling major intrusions.

Follow root cutting with thorough flushing to remove debris and prevent immediate re-clogging. Consider chemical root treatments after mechanical removal to inhibit regrowth, but ensure compatibility with your plumbing system and local environmental regulations. Regular maintenance prevents minor root intrusions from developing into major blockages.

Grease and Scale Removal

Accumulated grease and mineral scale require specific approaches that differ from typical debris removal techniques. Use heated water flushing in conjunction with drain snake operations to soften hardened deposits, making them more susceptible to mechanical removal. Scraping attachments work well for scale removal, while spiral heads help break up grease accumulations.

Multiple passes may be necessary for complete grease and scale removal, especially in commercial kitchen applications or areas with hard water conditions. Combine mechanical cleaning with appropriate chemical treatments for optimal results, but ensure proper ventilation and safety precautions when using chemical products in enclosed drain systems.

Cost-Effective Drain Maintenance

Preventive Maintenance Schedules

Implementing regular drain snake maintenance schedules prevents major blockages while extending plumbing system lifespan. Monthly light cleaning of main drains removes accumulating debris before it becomes problematic, while quarterly deep cleaning addresses potential buildup in hard-to-reach areas. Document maintenance activities to track patterns and identify recurring problem areas.

Seasonal maintenance addresses specific concerns such as leaf accumulation in outdoor drains, holiday cooking residues in kitchen systems, and increased usage patterns during busy periods. This proactive approach reduces emergency service calls while maintaining optimal drain performance throughout the year, saving money on costly repairs and replacements.

DIY versus Professional Services

Understanding when to use personal drain snake equipment versus hiring professional services helps optimize maintenance costs while ensuring appropriate problem resolution. Simple clogs in accessible locations respond well to DIY approaches, while complex blockages or main line issues typically require professional expertise and specialized equipment capabilities.

Evaluate the total cost of ownership for drain snake equipment, including initial purchase price, maintenance costs, and storage requirements. For occasional use, rental options might prove more economical, while frequent applications justify equipment purchase and proper training for effective use in various drain cleaning scenarios.

FAQ

How often should I use a drain snake for routine maintenance

For routine maintenance, use a drain snake monthly on main drains and quarterly on secondary drains to prevent major blockages from developing. High-use areas like kitchen sinks may require more frequent attention, especially if grease disposal occurs regularly. Monitor drain performance between cleanings to identify developing problems early, adjusting the maintenance schedule based on actual conditions and usage patterns in your specific plumbing system.

What size drain snake do I need for different applications

Choose drain snake diameter based on pipe size and blockage type. Quarter-inch cables work well for small residential drains and minor clogs, while half-inch cables handle standard household applications effectively. Three-quarter-inch or larger cables are necessary for main sewer lines and commercial applications. Cable length should exceed the distance to the blockage by at least 25 feet to ensure adequate reach and maneuverability during cleaning operations.

Can a drain snake damage my pipes

When used properly, drain snakes rarely damage pipes, but incorrect technique can cause problems in older or fragile plumbing systems. Avoid excessive force, use appropriate cable sizes, and rotate cables in the correct direction to minimize damage risk. Clay pipes, older cast iron systems, and thin-wall PVC installations require extra care during drain snake operations. If you encounter unusual resistance or hear grinding sounds, stop immediately and consider professional evaluation.

What should I do if the drain snake gets stuck

If a drain snake becomes stuck, avoid pulling forcefully, which can break the cable or damage pipes. Try reversing the rotation direction while applying gentle backward pressure to release the cable from the obstruction. Work the cable back and forth in small increments to gradually free it from tight spots. If these techniques fail, professional assistance may be necessary to safely retrieve the equipment and address the underlying blockage problem.