Hidden pipe problems can cause significant damage to residential and commercial properties before becoming visible to the naked eye. Traditional diagnostic methods often require invasive procedures, costly excavation, or extensive wall demolition to locate issues within plumbing systems. Modern diagnostic technology has revolutionized how professionals identify and assess pipe conditions through advanced visual inspection techniques. A plumbing camera provides non-invasive solutions that save time, reduce costs, and deliver accurate assessments of pipe integrity without disrupting property structures.

Advanced Blockage Detection and Location

Identifying Partial and Complete Obstructions

Professional plumbing cameras excel at detecting various types of blockages that might not manifest obvious symptoms initially. These sophisticated devices can identify grease buildup, hair accumulation, food debris, and foreign objects lodged within pipe systems. The high-resolution imaging capabilities allow technicians to distinguish between different obstruction materials and assess their density levels. Early detection prevents complete blockages that could result in sewage backups, flooding, or expensive emergency repairs.

The precision location features enable technicians to pinpoint exact blockage positions within complex pipe networks. This accuracy eliminates guesswork and reduces the need for exploratory excavation or wall removal. Camera systems provide real-time distance measurements from entry points, allowing crews to access problem areas efficiently. Professional-grade equipment includes footage recording capabilities that document blockage conditions for insurance claims or future reference.

Root Intrusion and Vegetation Damage Assessment

Tree roots represent one of the most destructive forces affecting underground plumbing systems, particularly in older neighborhoods with mature landscaping. Plumbing cameras reveal root intrusions that begin as hairline cracks and gradually expand into major structural compromises. The visual inspection process identifies root penetration points, growth patterns, and the extent of pipe damage without requiring immediate excavation. This information guides targeted repair strategies that address both current damage and prevent future intrusions.

Camera inspections document seasonal root growth patterns that affect pipe systems differently throughout the year. Spring and summer months typically show increased root activity, while winter inspections reveal structural damage from root expansion cycles. Professional technicians use camera footage to develop comprehensive root management plans that combine mechanical removal, chemical treatments, and pipe reinforcement strategies. These preventive approaches extend pipe system lifespans and reduce recurring maintenance costs.

Structural Integrity and Pipe Condition Analysis

Crack Detection and Joint Failure Identification

Microscopic cracks in pipe walls often precede catastrophic failures by months or years, making early detection crucial for preventive maintenance programs. Advanced plumbing camera systems utilize high-definition sensors that reveal hairline fractures invisible to conventional inspection methods. These detailed visual assessments help property owners prioritize repair schedules and budget for necessary maintenance work. Professional documentation includes crack measurement capabilities that track deterioration rates over time.

Joint failures represent critical vulnerabilities in pipe systems where connections between sections become compromised through age, ground movement, or thermal expansion. Camera inspections reveal separated joints, misaligned connections, and deteriorating gasket materials before they result in leaks or structural failures. The visual evidence helps technicians determine whether repairs require simple resealing procedures or complete joint replacement. This information guides cost-effective repair strategies that address underlying causes rather than temporary fixes.

Corrosion and Material Degradation Monitoring

Metal pipes experience various forms of corrosion that compromise structural integrity and water quality over extended periods. Camera inspections document rust formation, scale buildup, and material thinning that indicates replacement needs. The visual assessment process reveals corrosion patterns specific to different pipe materials, water chemistry conditions, and environmental factors. Professional technicians correlate camera findings with water quality testing to develop comprehensive pipe rehabilitation programs.

Plastic pipe systems experience different degradation patterns including stress cracking, UV damage, and chemical deterioration that affect performance characteristics. Camera technology identifies early warning signs of material failure including surface irregularities, color changes, and flexibility loss. These visual indicators help predict remaining service life and guide replacement timing decisions. Documentation provides valuable information for warranty claims and insurance assessments related to pipe system failures.

Water Flow and Drainage Efficiency Evaluation

Slope and Gradient Assessment

Proper drainage requires specific pipe slopes that maintain adequate water flow velocities for waste transport and system cleaning. Camera inspections reveal incorrect gradients that cause waste accumulation, slow drainage, and recurring blockage problems. The visual assessment process identifies low spots where debris collects and high points that restrict flow patterns. Professional-grade equipment includes leveling features that measure actual pipe slopes against engineering specifications.

Settling foundations and ground movement often alter original pipe gradients over time, creating drainage efficiency problems that worsen gradually. Camera technology documents slope changes that require correction through pipe adjustment or replacement procedures. The visual evidence helps contractors develop repair strategies that restore proper drainage characteristics while minimizing property disruption. These assessments prevent recurring drainage problems that result from inadequate slope correction attempts.

Cross-Connection and Backflow Risk Identification

Improper connections between different plumbing systems create health hazards through potential contamination pathways that compromise water safety. Camera inspections identify unauthorized connections, damaged backflow prevention devices, and system modifications that violate plumbing codes. The visual documentation helps property owners address compliance issues before they result in regulatory violations or health department citations. Professional assessments include recommendations for proper isolation and protection measures.

Storm water infiltration into sanitary sewer systems creates capacity problems and treatment facility overloads during heavy rainfall events. Camera technology reveals improper connections where surface drainage enters sewage lines through damaged joints, cracked pipes, or deliberate illegal connections. These findings guide targeted repair programs that separate storm and sanitary systems according to municipal requirements. Proper system isolation reduces treatment costs and prevents environmental violations.

Preventive Maintenance and System Optimization

Regular Inspection Scheduling and Documentation

Systematic camera inspection programs enable property managers to transition from reactive emergency repairs to proactive maintenance strategies that reduce long-term costs. Regular visual assessments document gradual changes in pipe conditions that inform replacement planning and budget preparation. The inspection intervals depend on pipe age, material type, usage patterns, and environmental conditions affecting system performance. Professional documentation creates valuable maintenance histories that support warranty claims and insurance requirements.

Digital recording capabilities preserve inspection results for comparison purposes during subsequent evaluations, enabling technicians to track deterioration rates and repair effectiveness. Time-stamped footage provides legal documentation for insurance claims, warranty disputes, and regulatory compliance reporting. The visual evidence supports professional recommendations for system upgrades, replacement priorities, and maintenance schedule adjustments. Comprehensive documentation demonstrates due diligence in property maintenance responsibilities.

Cost-Benefit Analysis and Repair Prioritization

Camera inspection results enable property owners to make informed decisions about repair timing, scope, and methodology based on actual conditions rather than assumptions. The visual evidence supports cost-benefit analyses that compare repair costs against replacement alternatives for different pipe sections. Professional assessments help prioritize maintenance budgets toward high-risk areas that pose immediate threats to property integrity. Strategic repair planning prevents emergency situations that require expensive after-hours service calls.

Insurance companies increasingly require documented maintenance programs that demonstrate responsible property management practices for coverage approval. Camera inspection records provide evidence of proactive maintenance efforts that may reduce premium costs or support claim settlements. The professional documentation helps property owners negotiate favorable insurance terms based on demonstrated risk management practices. Regular inspections also identify conditions that require immediate attention to maintain coverage validity.

FAQ

How often should plumbing camera inspections be performed

The frequency of plumbing camera inspections depends on several factors including pipe age, material type, and usage patterns. Most professionals recommend annual inspections for commercial properties and every two to three years for residential systems. Older pipe systems or those with previous problems may require more frequent evaluations. Properties with mature landscaping should consider annual inspections to monitor root intrusion risks.

What pipe sizes can plumbing cameras inspect effectively

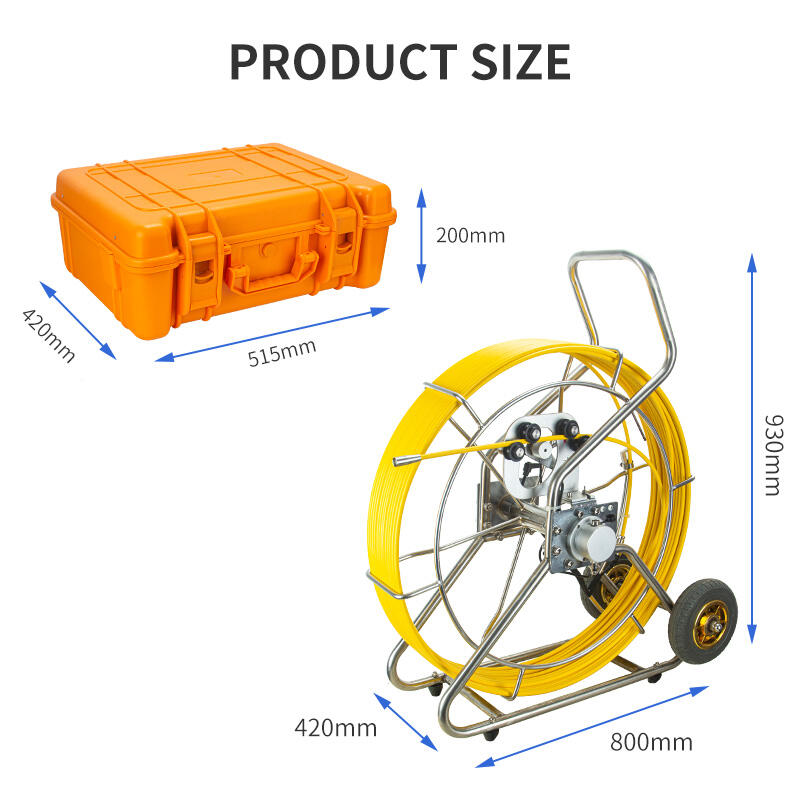

Modern plumbing camera systems accommodate pipe diameters ranging from 1.5 inches to 48 inches or larger depending on equipment specifications. Residential drain lines typically range from 2 to 6 inches, while commercial systems may require larger capacity equipment. Professional-grade cameras include interchangeable heads and cable systems designed for different pipe sizes and inspection requirements. Specialized equipment handles unique applications like storm drains and industrial process lines.

Can plumbing cameras detect problems in curved or angled pipes

Professional plumbing camera systems navigate complex pipe configurations including multiple bends, angles, and elevation changes through flexible cable design and articulating camera heads. The equipment follows natural pipe routes while maintaining image quality and control responsiveness. Advanced systems include self-leveling features that maintain proper camera orientation regardless of pipe angles. Some applications may require multiple entry points for complete system evaluation.

What additional services complement plumbing camera inspections

Comprehensive pipe evaluation often combines camera inspections with hydrostatic pressure testing, flow measurement, and water quality analysis for complete system assessment. Locating services help identify exact pipe positions for targeted repairs without excavation guesswork. Professional reports may include repair recommendations, cost estimates, and maintenance scheduling suggestions based on inspection findings. Some contractors offer package deals that combine inspection, cleaning, and minor repair services.