A clogged drain can quickly transform from a minor inconvenience into a major plumbing nightmare, disrupting daily routines and potentially causing costly water damage. When traditional methods like plunging or chemical drain cleaners fail to resolve stubborn blockages, a drain snake emerges as the professional-grade solution that homeowners and plumbers alike rely upon. This versatile plumbing tool, also known as a drain auger, provides mechanical action to break through even the most persistent clogs that accumulate deep within pipe systems.

Understanding how to properly operate a drain snake not only saves money on emergency plumber calls but also empowers homeowners to tackle drainage issues with confidence and precision. The mechanical advantage provided by these tools allows users to reach blockages located far beyond the reach of conventional cleaning methods, making them indispensable for comprehensive drain maintenance. Professional plumbers consider drain snakes essential equipment because they offer controlled, targeted action that can break through organic matter, hair accumulations, soap buildup, and other common clog materials without damaging pipe infrastructure.

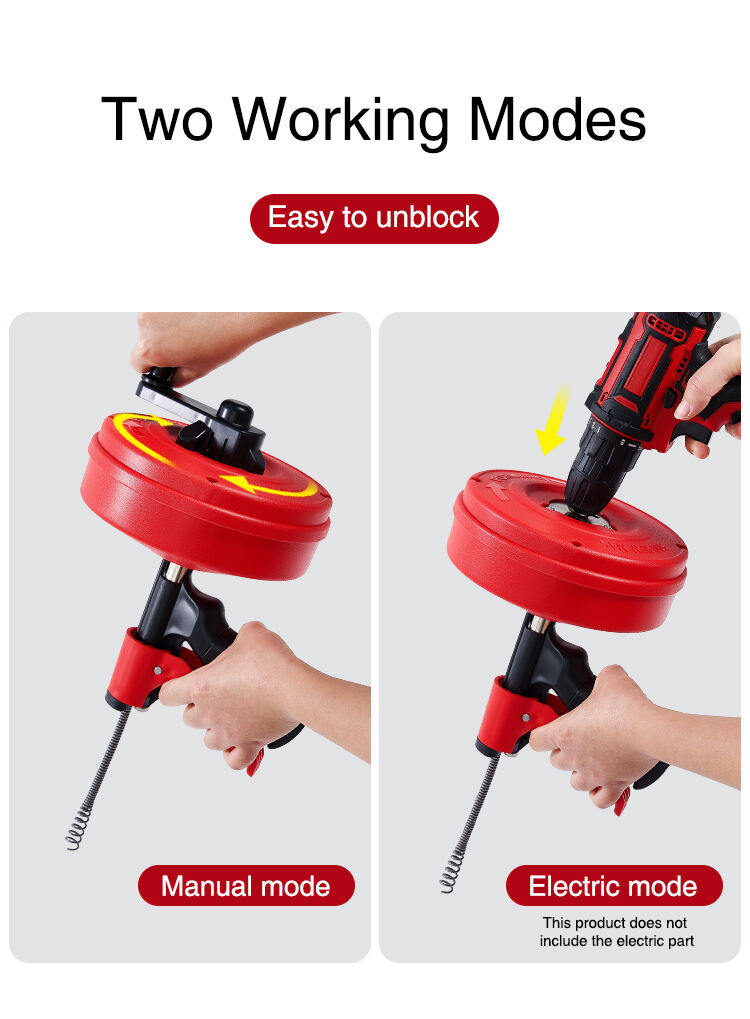

Modern drain snake technology has evolved significantly from simple cable designs to sophisticated systems that incorporate both manual and automatic operational modes. These advanced features enable users to adapt their approach based on specific clog characteristics and pipe configurations, ensuring optimal results across diverse plumbing scenarios. Whether dealing with kitchen sink grease accumulations, bathroom hair clogs, or main line obstructions, the right drain snake technique can restore proper water flow and prevent recurring drainage problems.

Understanding Drain Snake Types and Components

Manual vs Automatic Operation Modes

Manual drain snakes require physical rotation and feeding action from the operator, providing direct tactile feedback that experienced users value for precision control during clog removal operations. This hands-on approach allows operators to feel resistance changes as the cable encounters different obstruction types, enabling immediate technique adjustments for optimal penetration and extraction results. Manual operation particularly excels in delicate situations where excessive force could damage older pipe systems or when working around fragile fixtures that require gentle handling.

Automatic drain snakes incorporate motorized rotation systems that maintain consistent cable speed and torque, reducing operator fatigue during extended cleaning sessions while delivering steady mechanical action against stubborn blockages. These powered units often feature variable speed controls that allow users to match rotation rates to specific clog materials and pipe conditions, optimizing cutting action without overwhelming the system. Professional plumbers frequently prefer automatic systems for high-volume work because they deliver consistent results while minimizing physical strain during repetitive drain cleaning operations.

Cable Construction and Length Specifications

High-quality drain snake cables utilize spring steel construction that provides optimal flexibility for navigating complex pipe configurations while maintaining sufficient rigidity to push through dense blockages without buckling or binding. The cable diameter directly impacts penetration capability, with thicker cables offering greater cutting power for substantial clogs while thinner variants excel in tight spaces and delicate pipe systems. Cable length specifications typically range from 25 feet for residential applications to 100 feet or more for commercial and main line cleaning operations.

Professional-grade cables incorporate specialized tip configurations designed for specific clog types, including corkscrew augers for hair removal, cutting blades for root intrusion, and retrieval hooks for extracting foreign objects from pipe systems. The cable housing system prevents kinking and provides smooth feeding action that reduces operator effort while protecting the cable from premature wear during storage and transportation. Understanding cable specifications ensures optimal tool selection for specific drainage challenges and helps prevent equipment damage during aggressive cleaning operations.

Pre-Operation Safety and Preparation

Personal Protective Equipment Requirements

Proper safety gear forms the foundation of successful drain snake operations, beginning with heavy-duty work gloves that protect hands from sharp cable edges, contaminated materials, and potential chemical residues that may be present in drainage systems. Eye protection becomes critical when working with powered units or when debris ejection might occur during aggressive cleaning actions, particularly in vertical pipe configurations where material can spray upward unexpectedly. Appropriate clothing should cover exposed skin areas to prevent contact with sewage-contaminated water and cleaning chemicals that may be present in the pipe system.

Respiratory protection may be necessary when working in confined spaces or when dealing with sewer gases that can accumulate during extensive drain cleaning operations, particularly in basement installations or older building systems with inadequate ventilation. Non-slip footwear provides essential stability when working around wet surfaces and slippery bathroom or kitchen environments where drain snake operations commonly occur. Professional operators also recommend having emergency eyewash solutions readily available when working with chemical drain cleaners or in situations where contaminated material contact is possible.

Drain Assessment and Access Preparation

Thorough drain assessment begins with identifying the specific location and nature of the blockage through visual inspection and water flow testing to determine appropriate snake size and technique selection. Removing drain covers, pop-up assemblies, and other hardware provides unobstructed access while protecting these components from damage during cable insertion and rotation operations. Clearing the surrounding work area prevents accidents and provides adequate space for cable management during operation, particularly important with longer cables that require careful handling to prevent tangling.

Water level management involves either draining standing water to improve visibility and reduce mess or maintaining specific water levels that aid in clog location and removal effectiveness depending on the specific drainage situation. Testing the drain snake operation and cable condition before insertion prevents mid-operation failures that could complicate clog removal or potentially damage the pipe system. Proper preparation also includes having cleanup materials readily available for immediate response to any overflow or debris discharge that occurs during the cleaning process.

Step-by-Step Operating Procedures

Initial Cable Insertion and Positioning

Cable insertion begins with careful feeding of the snake tip into the drain opening while maintaining gentle downward pressure to guide the cable past the initial pipe bend without forcing or jamming the mechanism. The operator should feel the cable moving freely through the pipe system, with any resistance indicating potential obstruction locations that require careful navigation or immediate attention. Proper cable positioning ensures optimal contact angles with the pipe walls while preventing damage to fixture surfaces or internal pipe coatings that could create future maintenance issues.

Gradual advancement allows the cable to follow natural pipe contours while building momentum toward the blockage location, with experienced operators recognizing the distinct feel differences between normal pipe navigation and actual clog contact. Maintaining steady cable tension prevents slack formation that could cause tangling or binding during rotation operations, particularly important in complex pipe configurations with multiple direction changes. The insertion process should proceed at a controlled pace that allows for immediate response to unexpected resistance or feedback changes that indicate approaching obstructions.

Clog Engagement and Removal Techniques

Effective clog engagement requires recognizing the distinctive resistance increase that occurs when the cable tip contacts blockage material, followed by appropriate technique selection based on the specific obstruction characteristics and pipe system configuration. Rotational action should begin slowly to assess clog density and composition before increasing speed and pressure to match the material resistance level encountered. The operator must balance aggressive cleaning action with pipe protection, particularly in older systems where excessive force could cause joint separation or pipe wall damage.

Breakthrough techniques vary depending on blockage type, with organic materials typically requiring sustained rotational cutting action while foreign objects may need careful extraction procedures to prevent pushing them deeper into the system. Alternating between advancement and retraction motions helps break up stubborn clogs while allowing debris removal that prevents re-accumulation downstream from the original blockage location. Professional operators emphasize patience during this phase, as rushing the process often leads to incomplete clog removal or cable damage that compromises future cleaning effectiveness.

Advanced Troubleshooting and Problem Resolution

Managing Cable Binding and Resistance Issues

Cable binding typically occurs when excessive rotational force causes the snake to twist against pipe walls or clog material, requiring immediate cessation of rotation followed by careful reverse operation to release the binding condition. Recognizing early warning signs of binding, such as increased motor strain or unusual vibration patterns, prevents cable damage and potential pipe system harm that could result from continued forced operation. Proper technique involves alternating rotational directions while applying gentle extraction pressure to work the cable free without causing permanent deformation or breakage.

Resistance management strategies include adjusting rotation speed to match encountered material density while maintaining consistent advancement pressure that prevents cable buckling or coiling within the pipe system. Experienced operators learn to distinguish between normal operational resistance and problematic binding conditions through tactile feedback and equipment response patterns that indicate potential complications. When binding occurs in automatic units, immediate power disconnection followed by manual extraction procedures prevents motor damage while preserving cable integrity for continued operation.

Dealing with Complex Blockage Scenarios

Multiple blockage situations require systematic approach techniques that address each obstruction individually while preventing debris redistribution that could create new clogs downstream from the original problem areas. Complex root intrusions often necessitate specialized cutting attachments combined with repeated passes to achieve complete removal, particularly in older sewer systems where tree root penetration creates dense, fibrous blockages. Chemical pre-treatment may be beneficial for certain organic blockages, but operators must ensure compatibility between cleaning agents and pipe materials to prevent system damage.

Foreign object removal demands careful technique modification to prevent pushing items deeper into the system, often requiring retrieval attachments or alternative extraction methods that protect both the object and pipe integrity during removal operations. Grease accumulations typically respond best to sustained mechanical action combined with hot water flushing to dissolve and carry away loosened material before it can re-solidify in cooler pipe sections. Professional assessment becomes necessary when standard drain snake techniques fail to resolve persistent blockages, as underlying pipe damage or system design issues may require specialized repair approaches.

Post-Operation Maintenance and Storage

Cable Cleaning and Inspection Procedures

Thorough cable cleaning immediately following each use prevents contamination buildup and corrosion development that could compromise future performance while extending equipment service life significantly. High-pressure water rinses remove organic debris and chemical residues while allowing visual inspection of cable condition including identification of wear patterns, kinks, or damage that requires attention before storage. Disinfection procedures using appropriate antimicrobial solutions eliminate harmful bacteria and pathogens that accumulate during sewage system contact, protecting both equipment and operator health during subsequent handling.

Cable inspection focuses on identifying stress points, wear patterns, and potential failure locations that could cause operational problems or safety hazards during future use, with particular attention to connection points and high-flex areas that experience maximum stress. Proper lubrication of moving components maintains smooth operation while preventing corrosion in storage environments, particularly important for equipment exposed to moisture and chemical residues during drain cleaning operations. Documentation of cable condition and usage history helps establish maintenance schedules and replacement timing that prevents unexpected failures during critical cleaning operations.

Proper Storage and Equipment Care

Appropriate storage environments protect drain snake equipment from temperature extremes, moisture accumulation, and chemical exposure that could cause premature degradation of cables, housing components, and mechanical systems. Coiling techniques that prevent kinking while maintaining proper cable memory ensure ready availability for future operations without time-consuming straightening procedures that delay emergency response capabilities. Climate-controlled storage areas prevent corrosion development while protecting rubber components and electrical systems from environmental damage that could compromise operational safety and effectiveness.

Regular maintenance schedules include lubrication of rotating components, inspection of electrical connections, and replacement of wear items according to manufacturer specifications and usage intensity patterns. Proper inventory management ensures availability of replacement parts and consumable items while maintaining equipment readiness for both planned maintenance and emergency response situations. Professional operators maintain detailed service records that track equipment performance and guide preventive maintenance decisions that maximize operational reliability while minimizing unexpected downtime and repair costs.

FAQ

What size drain snake do I need for different pipe diameters?

Pipe diameter directly determines appropriate snake cable size, with 1/4-inch cables suitable for bathroom sink drains and shower drains, while 3/8-inch cables work best for kitchen sinks and floor drains that handle larger debris volumes. Main sewer lines typically require 1/2-inch or larger cables that provide sufficient cutting power for root intrusions and major blockages encountered in primary drainage systems. The cable should be approximately one-third the pipe diameter to ensure effective cleaning action while preventing binding or damage to pipe walls during operation.

How do I know when the clog is completely removed?

Complete clog removal is indicated by sudden reduction in cable resistance combined with improved water flow when testing the drain system after snake withdrawal from the pipe. The cable should move freely through previously blocked areas without encountering the solid resistance that characterized the original blockage location. Final confirmation involves running water through the system at normal flow rates while observing drainage speed and listening for the gurgling sounds that indicate remaining partial obstructions requiring additional cleaning attention.

Can I damage my pipes using a drain snake incorrectly?

Improper drain snake technique can cause pipe damage including joint separation in older systems, scratching of fixture surfaces, and potential perforation of corroded pipe walls when excessive force is applied during operation. Forcing cables through resistant areas or using oversized equipment for delicate pipe systems creates risk of structural damage that requires professional repair services. Following proper insertion techniques, appropriate force levels, and manufacturer guidelines minimizes damage risk while ensuring effective clog removal in most residential and commercial drainage applications.

What should I do if my drain snake gets stuck in the pipe?

A stuck drain snake requires immediate cessation of rotational force followed by gentle alternating push-pull motions combined with slight rotational reversals to release binding conditions without causing cable or pipe damage. Never attempt to force a stuck cable through brute strength, as this typically worsens the binding condition while potentially causing expensive pipe system damage. If manual extraction attempts fail, professional plumbing services should be contacted immediately, as specialized equipment and techniques may be required to safely remove the cable while preserving pipe system integrity.